Family farms in Vermont come in all varieties and sizes, but there aren’t many that can boast the pedigree of the Pine Valley Farm in Shrewsbury.

Standing in the kitchen of her 1800s farmhouse, Julanne Smith Sharrow is proudly displaying a genealogical chart she’s ingeniously clipped to a coat hanger. The poster-sized paper is crowded with the neatly written record of several centuries of family history, including John (the Miller) Smith, who is recorded in 1640 as one of the earliest settlers of Rhode Island.

“It holds fifteen generations and it’s still not enough,” she says of the chart, turning the hanger to indicate where the back of a second page accommodates more ancestors. “This is what I’ve been working on for twenty years. I don’t know if I’ll ever finish it.”

A trim, energetic woman with a gregarious personality and a sprinkle of mischief, Julanne is the seventh generation of her family on the farm. Their Shrewsbury roots first took hold in 1780 with the arrival of Nehemiah Smith from Rhode Island. A veteran of both the Revolutionary and French and Indian wars, Nehemiah can also be credited as one of the town’s founding fathers, since he was one of the first three selectman elected when it was incorporated in 1781.

From humble beginnings—a lean-to built against a boulder across the road, Nehemiah eventually assumed ownership of a more comfortable dwelling. The family isn’t sure how it came about, but they think he might possibly have benefited from a dispute between fellow war veteran Lemuel White and the land surveyors who were becoming active during that time in building roads and laying out land parcels.

“This was Lemuel White’s tavern,” Julanne explains, gesturing around her cozy living room, which is judged to be the oldest part of the existing farmhouse. “But Lemuel liked to drink and gamble, so we figure he lost the tavern because he didn’t pay the surveyors.”

For the earliest settlers in Shrewsbury, a good deal of their initial efforts went into clearing the forested land and converting it to tillable fields. This produced one of their few cash crops—a harvest of trees to sell for making potash. At that time it was a common industrial ingredient used in a variety of products, from soap to gunpowder. For the first several generations farming was largely a subsistence operation, but with Julanne’s grandfather, Harold Smith, born in 1895 and the fifth generation to take over the farm, things began to change.

“I’ve been reading up on him and going through old scrapbooks,” was doing Triple A breeding before the guy who invented it was even born. My father would get so mad because we’d get a barn full of gorgeous cows and my grandfather would back up the truck and load them all up and take them off for sale. That’s where he made his money.”

When Harold died unexpectedly in 1957, the farm passed to Julanne’s father, Chandler, whose talents and interests took him in a somewhat different direction.

“My father really loved mechanical things. He loved to invent, make, build. He built a hay elevator in the barn that went up, over, around and through. It was hundreds of feet long. And…” she raises an eye in amused exasperation. “He invented a self-propelled chopper, but was discouraged by the neighbors from patenting it.”

Although the two generations before and after her graduated from Vermont Technical College (known as the Vermont Agricultural School when her father and grandfather attended), Julanne took a more business-oriented path. “They sent me to secretarial school,” she says. “I loved the numbers, so I ended up getting into auditing, listing, doing the books for farm and the sugar house, and I’ve been treasurer for every organization in town.”

Although the two generations before and after her graduated from Vermont Technical College (known as the Vermont Agricultural School when her father and grandfather attended), Julanne took a more business-oriented path. “They sent me to secretarial school,” she says. “I loved the numbers, so I ended up getting into auditing, listing, doing the books for farm and the sugar house, and I’ve been treasurer for every organization in town.”

She also went off into the world for a time, married and had a son, and when she brought her family back to the farm, her father had a new assignment for her.

“He said, why don’t you feed the calves for me. Sure enough, I killed ‘em all.”

What?! No!

“Oh yes!” she exclaims, attributing the disaster in part to the conditions on the second floor of the barn where the calves were raised. What once had been a warm environment grew cold and damp once a milking parlor was installed and the cows were housed elsewhere.

“So my father told me to start making ‘Polish puddin’,” Julanne says. “You take the colostrum milk and put it in a barrel and let it pickle and then feed it back to the calves. We experimented and I kept playing with it. It’s just like yogurt. You stir it every day, you let it rise up like bread and then it goes back down and it’s ready to use. I fortify it with a little powdered milk. Well, now I’ve been feeding calves for 49 years with my pickled colostrum and haven’t lost a single calf. I swear by it.”

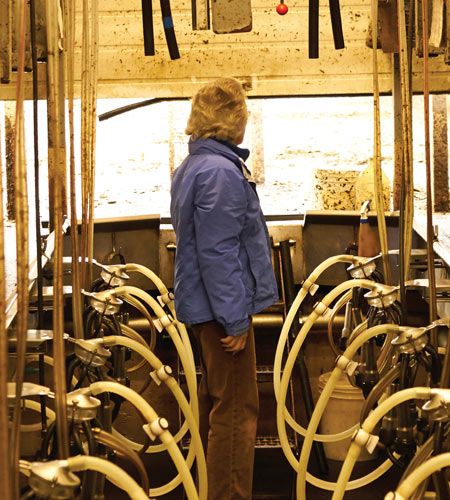

She inherited the farm when Chandler Smith died of a heart attack in 1984, holding the business steady until her son Neal graduated. Now he, his younger brother Chad, and his son Chandler jointly work the farm, which currently comprises 500 acres, with a modern milking parlor and multiple barns and farm buildings. Their herd of Holsteins stands at 100, and the milk goes to the Agrimark-Cabot facility in Middlebury for cheese production.

Pine Valley Farm could be considered a smaller dairy operation, but it has grown more than Nehemiah Smith ever could have imagined, and its size is one that Julanne’s son Neal thinks is just right, because on this day in late March, the small sugar house just down the road from the main farm is where most of the action is, around the clock, seven days a week.

After working with the former owner of the sugar house for several years, the family has owned the business outright for the past five. The first sap was boiled in January this year, and although March got off to a slow start it is running fast now and they are racing to keep up with it.

“I was here all last night with my little beagle, getting up every two hours to check on things,” Neal says. “We were a thousand gallons behind last year two days ago, but by the end of today, we’ll be caught up.”

They have a sugarbush of 16,000 trees to tap, an enterprise that takes approximately 150 hours. “We try to tap a tree a minute,” says Neal’s son Chandler. “We walk every main line at least two or three times.”

“We’ve got more than 15 miles of main line,” Neal says. “They were at the end of their life when we took over so we’re replacing them fairly quickly. After 15 or 20 years, the sun gets after them and they start coming apart and cracking.”

While a lot of work is going into routine maintenance and management activities, it’s also clear from a tour of the sugar house— where several “Smith-styled” pieces of equipment are in use—that the knack for invention has been successfully passed from one generation to the next.

“Oh yeah, we like to make stuff,” Neal laughs. “I might buy something incomplete from a company and then we finish it. We’ve got a lot of equipment that I’ve made—a firewood processor, a feed cart for feeding my calves, a self-propelled round bale wrapper that loads itself.” He indicates the large vacuum pump system housed in a separate outbuilding that is sending sap down to the two bulk tanks stored below it. “You can’t really buy something like this, so we built it. We experimented with different pumps and other parts.”

Along with their own home-manufactured equipment, the Sharrows also sell and service equipment for H20 Distributors, primarily reverse osmosis systems, which perform the critical function of separating the sugar from the water as the sap is pumped through it.

Within the system are filters with permeable membranes so tight that a water molecule can be pushed through while the sugar molecule remains. The resulting pure, mineral-free water is then pumped back out into separate storage tanks.

Checking the gauges on his own reverse osmosis machine, Neal is encouraged to see the sugar content is continuing to rise from where it was a few days earlier. When it begins to fall again, that will signal an approaching end to the season. By then, he hopes to have produced 8,000 gallons of syrup, all of which is sold to Butternut Mountain Farm in Morrisville, Vermont. After a summer break, the cycle will begin again.

“We need a lot of time to get out in the woods,” Neal says. “My brother wants to get out there in the early fall, before deer season, to check all the lines. If a tree came down on one, we want to get it picked up, we don’t want it to get frozen.”

To take best advantage of both the dairy and maple-sugaring ends of its business, Pine Valley employs a seasonal schedule to maximize the time that can be devoted to each, and Neal says his relationship with Phoenix Feeds fits easily into that model as well.

“I haven’t had anybody else since they’ve been in business, and I went after them. We’re a small farm and don’t really push the cows, but I needed some changes in my feed and the other place wouldn’t return my calls.”

“I haven’t had anybody else since they’ve been in business, and I went after them. We’re a small farm and don’t really push the cows, but I needed some changes in my feed and the other place wouldn’t return my calls.”

With a nutrition plan in place, Neal can take his own samples and send them to Phoenix Dairy Nutrition Specialist Shane Keady. “He’ll get right back to me. He’ll come when I need him to, but we do a lot of tweaking that way, through email communications.”

To free up time during the sugaring season, the farm does all its breeding from November to the first of the year. “So right now, we’re just milking and they’re beyond 200 days. They aren’t making a lot. We’ll get a few calves in August and the bulk of them in September.”

And when the calves arrive, Julanne will be ready for them. After 49 years, she is still in charge of birthing and raising the calves until they are weaned, and they are all within easy reach.

“It’s all right outside my back door,” she says. “I’ve got little pens here, there and everywhere, and one big pen where those calves can just run, hellitty-toot. The best thing in the world for them. I don’t see how people can raise calves all hitched in. I let mine RUN. I go out at nine o’clock at night to check everybody. Then I take a nap and at two or three in the morning I’m out there checking and feeding them.”

Along with raising the calves, she continues to do the books for the farm, while remaining active in local volunteer work. She serves as a member and registrar of the Daughters of the American Revolution, and is a participating member in other organizations such as New England Women, and the Daughters of Founders and Patriots of America.

She also makes lunch for her farm boys—seven days a week— and still has a bit of time left to dig farther into the roots of Nehemiah Smith and his forebears.

“I haven’t found a Mayflower line yet,” she says, with a glint in her eye. “I’m still looking.”